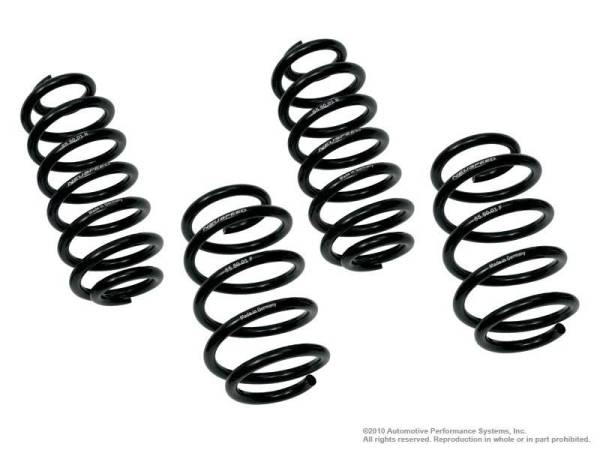

Neuspeed Sport Spring Kit for VW MK7 GTI / Golf & Audi 8V A3 FWD

Description

VW/Audi Performance Parts: Neuspeed Sport Spring Kit for VW MK7 GTI / Golf & Audi 8V A3 FWD (55.70.07)

Product Features & Benefits

Lowering:

- Audi A3 1.8T: 1.2"/1.3'

- VW Golf 1.8T: 1.6"/1.6"

- VW GTI 2.0 TSI: 1.1"/ 1.1"

Spring Rate:

- NEUSPEED Front Spring Rate: 260 lbs/in

- NEUSPEED Rear Spring Rate: 290 lbs/in

- Original A3 1.8TSI FWD Spring Rate: Front - 130 lbs/in, Rear - 165 lbs/in

- Original GTI Spring Rate: Front - 175 lbs/in, Rear - 230 lbs/in

Additional Details

NEUSPEED Sport Springs are made from the highest quality spring steel for unmatched performance and safety, they will not set or sag. They are precision manufactured in the most technically advanced, state-of-the-art facility in Germany.

Every NEUSPEED spring is designed and tested at their R&D facility in Camarillo, California by their suspension engineers to deliver an aggressive look and high performance handling without ever compromising safety or ride quality, then put to the test on the street and track by performance driving professionals.

Enhance the look of your vehicle with a reduced fender well gap. NEUSPEED Sport Springs lower the vehicle center of gravity, reduce body roll for better handling and reduce front-end dive under heavy braking. The progressive spring rate design provides great ride quality and comfort.

Fitment:

- 2014+ Audi A3(8V) FWD 1.8T & 2.0T

- 2015+ VW MK7 GTI & Golf 1.8 TSI with independent rear suspension

10% OFF Installation

Save 10% off installation if you're a local to Las Vegas, NV by visiting our local shop, Eurotek Tuning. Call 888-967-5634 to make an appointment today.

Details

- 55.70.07

- 55.70.07

- Neuspeed

- Direct Ship (shipping times may vary)

- New

Categories

Shipping Information

- Item Requires Shipping

- 32.0 lbs.

- Free Shipping

- Direct Ship (shipping times may vary)

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

Write the First Review!